AEM V2 Water Methanol Injection Kit AEM

$ 512,95 $ 153,89

Water/methanol injection for forced induction (turbocharged or supercharged) gas-powered race engines is a proven means for effectively reducing engine inlet air temperatures and suppressing harmful detonation. This allows racers to reliably increase boost and advance ignition timing—without using high-octane racing fuel—for power gains of up to 20%. AEM’s Water/Methanol Injection Systems utilize the most robust hardware combined with more advanced features than any other comparably priced water/methanol system.

One is boost dependent for forced induction vehicles up to 35 PSI of boost (kit PN 30-3300). The Boost Dependent controller has an on-board manifold absolute pressure (MAP) sensor with a molded-in nipple for a boost hose pickup.

The second controller (Kit PN 30-3350) features a multiple input design that enables users to install AEM’s Water/Methanol Injection Kit on ultra-high boost vehicles (above 35 PSI) using a 0-5v voltage-based external MAP sensor.

Features:

- Reduces Air Inlet Charge Temps

- Reduces Detonation (Knock)

- Reduces Carbon Deposits

- Robust, Easy to Use Controller Design

- Simplified Wiring

- Integrated Boost Safe Feature

- Heavy-Duty High Pressure Injection Pump

- Low-Profile 1.15 Gallon Tank

- Machined Billet Injectors and Nozzles

- Revised Flow Control Strategy for More Linear Fluid Delivery

What’s Included:

- AEM V2 Water Methanol Injection Kit

| Select Boost Application | 0 – 35 PSI, 36+ PSI |

|---|

Fast Shipping and Professional Packaging

Due to our long-term partnership with UPS, FedEx, DHL and many other world-class carriers, we are able to offer a variety of shipping options. Our warehouse staff is highly skilled and will wrap your goods according to our precise and exact specifications. Before shipping the goods are thoroughly inspected and secured. We deliver to hundreds of thousands of customers every day in different countries. Our dedication to becoming the biggest online retailer around the globe is evident by this. The warehouses and centers of distribution are situated in Europe and the USA.

Please note that orders with multiple items are processed according to the specific item.

Before shipping, we will check the item thoroughly before sending the items. Most orders are shipped within 48-hours. Delivery time ranges between 3-7 days.

Returns

The stock is constantly changing and cannot be fully controlled by us due to the involvement of several entities, including the factory as well as our warehouse. Therefore, the actual inventory could change at any time. Please be aware it's possible your order could become unfulfilled when you have placed the order.

Our policy is valid for 30 days. If 30 days have gone without a trace since the purchase and we are unable to offer you a refund or exchange.

You are able to return an item if it is unused and is in the same state as the day you received it. It should also be in the original packaging.

Related products

Forced Induction

Uncategorized

Suspension

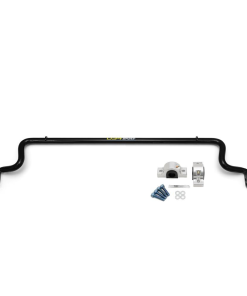

034Motorsport Billet Adjustable Front Sway Bar End Link Pair – Gen 1/1.5 R8 034Motorsport

Forced Induction

Uncategorized

034Motorsport 2-Piece 365mm Floating Front Brake Rotor Upgrade Kit – Audi R8 Gen 1/1.5 034Motorsport