JXB Performance Driveshaft Carrier – VW 7L Touareg and Porsche 9PA Cayenne JXB Performance

$ 249,99 $ 100,00

The stock center support bearing carrier holds the driveshaft in place with rubber so thin about 20 lbs of force moves it from center to the end of its travel. While that’s great for making sure no NVH makes it to the cabin, it doesn’t keep the bearing centered well under load, allows the bearing to sag over time and ruin the driveshaft alignment, and creates slop in the driveline during shifts and throttle application. Over time the OEM bushing sags and becomes brittle, eventually dry rotting and cracking. Even on the best-kept cars, the stock bushing can start to form cracks in as little as 5-10 years. When the bushing lets go, it can lead to excessive vibration and clunking and puts more stress on the bearing. To make matters worse, the stock carrier is molded onto the center support bearing, so it’s not easy to replace without special tools.

This upgraded unit keeps the driveshaft firmly in place at all times, and its solid construction ensures it will never wear out. The thick bushings ensure the driveshaft cannot move from center, maintaining driveshaft alignment at all times.

Two options are available for the bushings, both of which are many times over better than the stock bushing. We’ve paid close attention to the NVH levels associated with this upgrade. After extensive design iterations, we’ve come up with custom isolator bushings that separate the carrier from the body of the vehicle and mounting hardware. These carriers substantially reduce NVH levels.

The street bushings absorb most of the NVH from the drivetrain. Some light NVH is possible at some speeds in the form of a soft hum. With a modified exhaust or windows down you’ll probably never hear it.

The track bushings are for those who want no-compromise drivetrain performance. These may create a substantial amount of cabin noise. Not sure which is for you? They’re interchangeable so you can try them both.

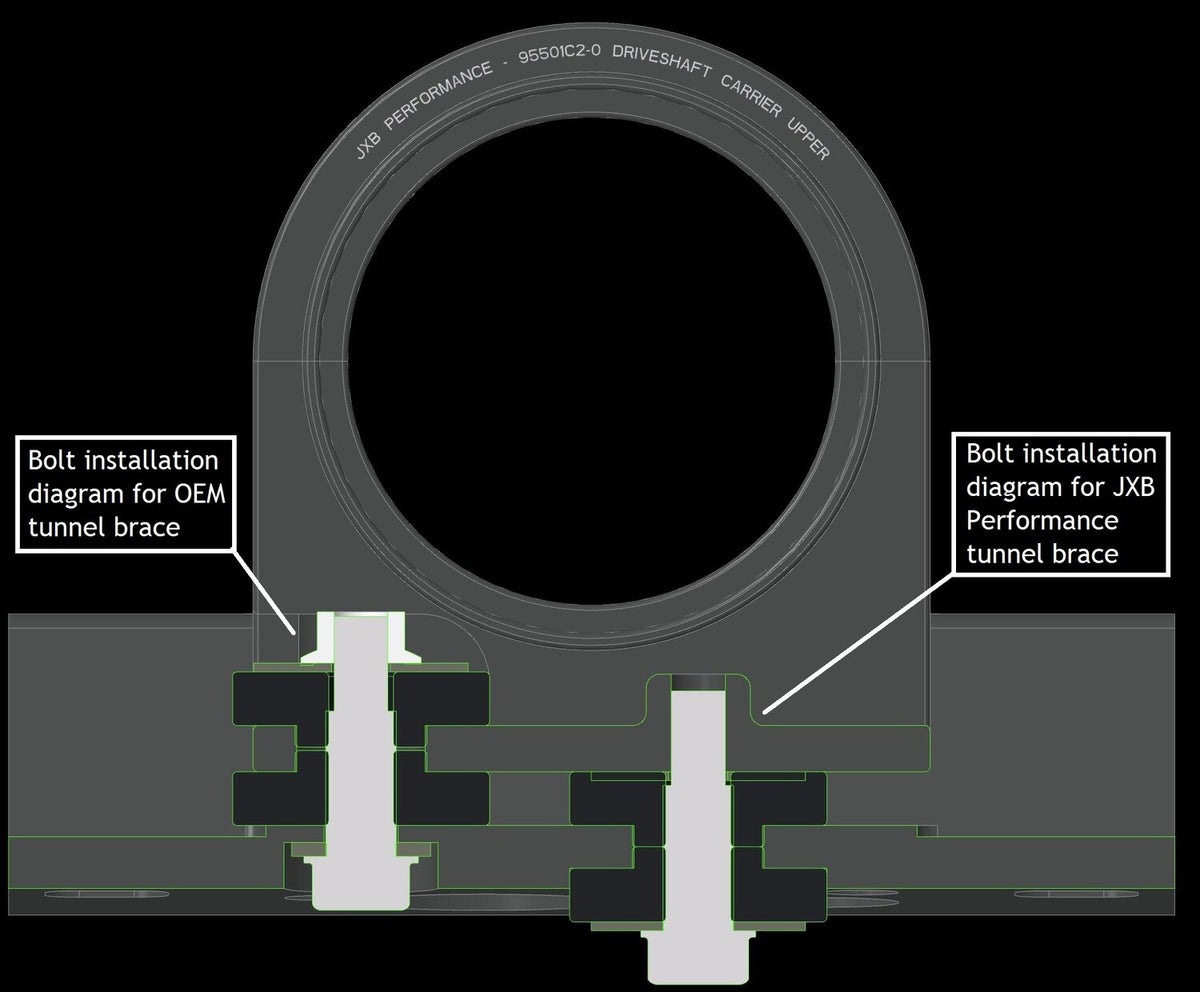

Installation doesn’t require disassembly of the driveshaft. The 2-part design clamps around the OEM bearing. The old carrier must be removed, so a cutting tool is required. There are 2 ways to bolt up the new carrier:

-

Option A

-

Illustrated using the left bolt below in the picture below, Option A is the only way to install the carrier using the OEM tunnel brace. You first clamp the carrier around the driveshaft, then a nut and bolt hold the carrier to the OEM brace. Access for the nut is tight, so the front of the driveshaft must be lowered to get a wrench on the nut. Once tight, the entire assembly is bolted up to the body. For a first-timer, installation will be about 1.5-2 hrs.

-

-

Option B

-

Illustrated using the right bolt below, Option B makes use of a custom tunnel brace to make installation faster and easier. The bottom half of the carrier can be bolted to the new tunnel brace while off the car, then special holes in the brace allow you to bolt the two halves together at the very end. This method doesn’t require lowering the front of the driveshaft. For a first-timer, installation will be about an hour.

-

Features:

- Available bushing stiffness: Street (Softer, Quieter), Track (Harder, Louder), or Both!

What’s Included:

- JXB Performance Driveshaft Carrier

| Select Bushings | Street, Track, Give Me Both! |

|---|---|

| Add Tunnel Brace? | No Thanks, Yes (+$100) |

Fast Shipping and Professional Packaging

Due to our long-term partnership with UPS, FedEx, DHL and many other world-class carriers, we are able to offer a variety of shipping options. Our warehouse staff is highly skilled and will wrap your goods according to our precise and exact specifications. Before shipping the goods are thoroughly inspected and secured. We deliver to hundreds of thousands of customers every day in different countries. Our dedication to becoming the biggest online retailer around the globe is evident by this. The warehouses and centers of distribution are situated in Europe and the USA.

Please note that orders with multiple items are processed according to the specific item.

Before shipping, we will check the item thoroughly before sending the items. Most orders are shipped within 48-hours. Delivery time ranges between 3-7 days.

Returns

The stock is constantly changing and cannot be fully controlled by us due to the involvement of several entities, including the factory as well as our warehouse. Therefore, the actual inventory could change at any time. Please be aware it's possible your order could become unfulfilled when you have placed the order.

Our policy is valid for 30 days. If 30 days have gone without a trace since the purchase and we are unable to offer you a refund or exchange.

You are able to return an item if it is unused and is in the same state as the day you received it. It should also be in the original packaging.

Related products

Forced Induction

Uncategorized

Uncategorized

034Motorsport 2-Piece 365mm Floating Front Brake Rotor Upgrade Kit – Audi R8 Gen 1/1.5 034Motorsport

Forced Induction